Various tantalum capacitor types find applications in today’s electronic circuits. But what is a tantalum capacitor? A tantalum capacitor is an electrolytic capacitor that utilizes tantalum metal and exhibits remarkable performance characteristics in a compact form. In general, tantalum electrolytic capacitors offer high capacitance and stability.

Tantalum capacitors find applications across a spectrum of electronic devices, from smartphones to medical equipment. Compared to aluminum electrolytic capacitors, these compact capacitors are pricier. This article dives into various aspects of different tantalum capacitor types and their uses. To explore other types of capacitors, take a look at our introductory guide to different capacitor types.

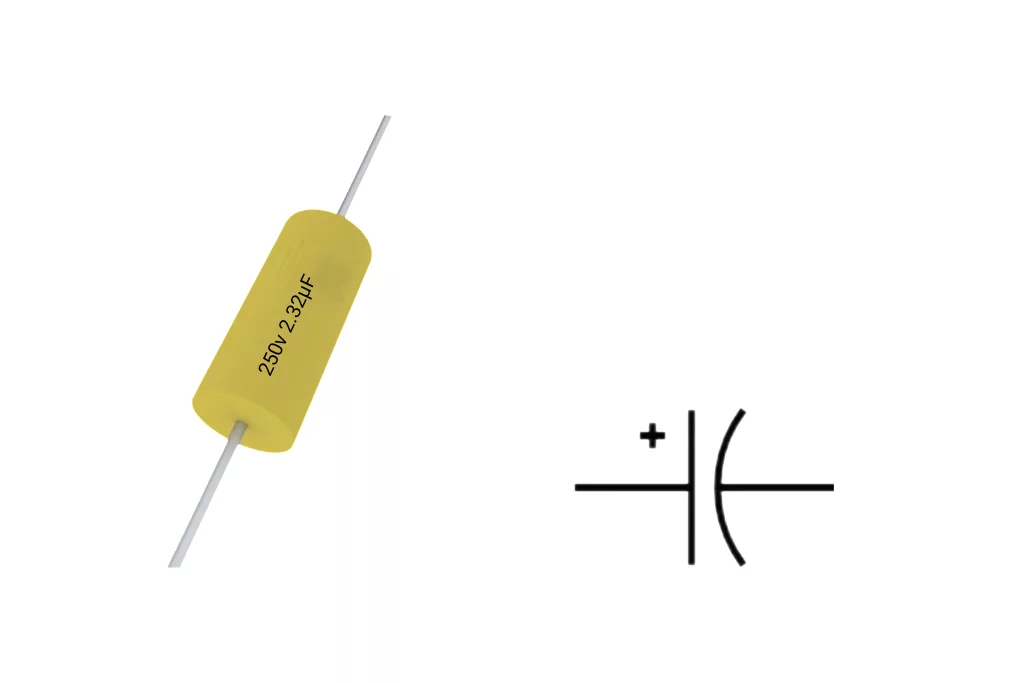

Tantalum capacitor polarity and symbol

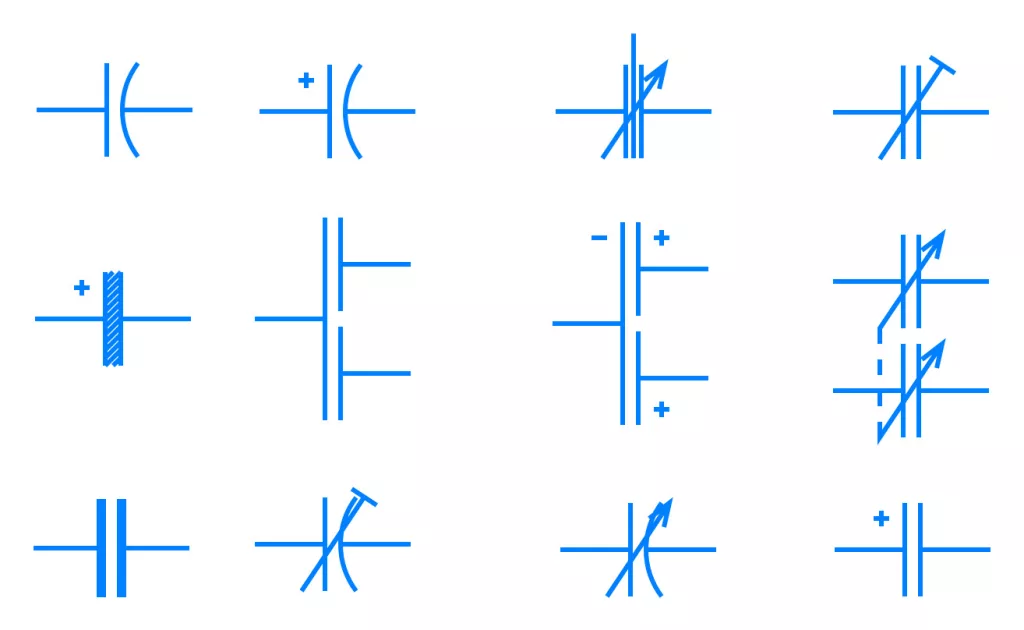

Like aluminum electrolytic capacitors, all tantalum capacitor types are polarized. This means that these capacitors have a specific orientation or polarity that must be observed during installation. By using tantalum capacitor markings on the body of a component, one can easily identify the positive and negative terminals. The standard polarized capacitor symbol for a polarized capacitor serves as a visual guide for the proper orientation of the component in circuit diagrams. Figure 1 shows a tantalum capacitor and the tantalum capacitor symbol.

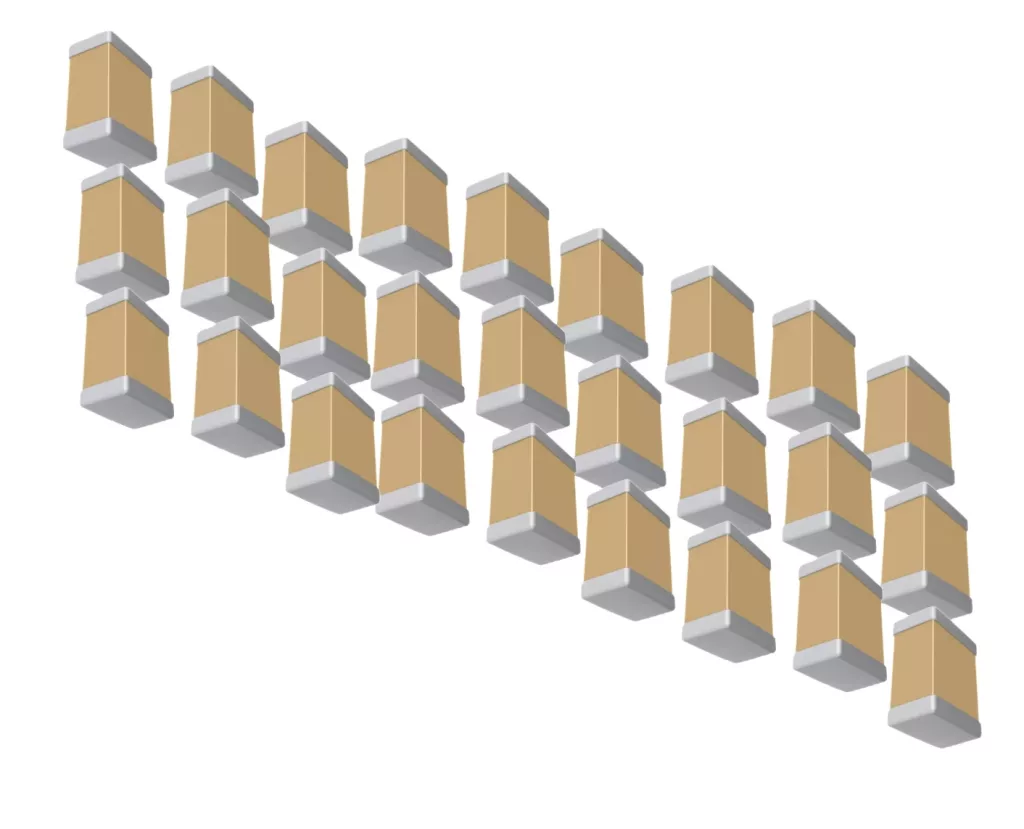

Axial, radial and SMD tantalum capacitor types

Tantalum capacitors come in various styles to cater to diverse needs of today’s electronic designs. Common configurations include surface mount device (SMD) chips, stacked smd chips, radial, and axial designs. SMD tantalum capacitors are compact and suitable for automated assembly processes. Radial tantalum capacitor styles excel in versatility while stacked chip tantalum capacitors offer high capacitance in a small space.

Axial tantalum capacitor styles ensure straightforward through-hole mounting and they find use in a wide range of applications. There are also axial hermetic tantalum capacitors, providing a sealed and durable option. This broad range of styles allows engineers to choose the most fitting configuration for their specific application needs, whether it’s maximizing space efficiency, ensuring durability, or meeting specific mounting requirements.

Tantalum capacitor construction

Tantalum capacitors utilize tantalum metal, which serves as the anode, and a thin oxide layer formed on its surface acts as the dielectric. The cathode, typically made of manganese dioxide, ensures conductivity. This oxide layer is pivotal, as it enables the efficient storage and release of electrical charge.

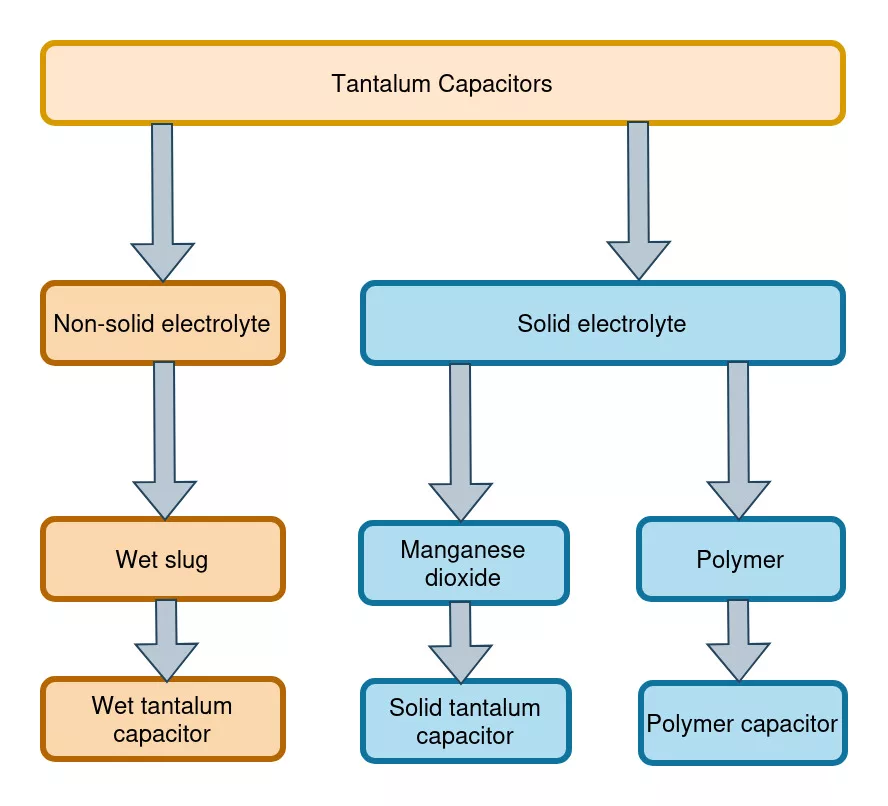

These capacitors come in various types, including those with liquid electrolyte for high capacitance, solid manganese dioxide for reliability, and polymer electrolyte for a balanced performance and space efficiency. Based on the electrolyte, there are three classes of tantalum capacitors: liquid electrolyte (wet electrolyte), solid manganese dioxide, and polymer. Figure 2 shows the classes of tantalum electrolytic capacitors and the electrolytes used in the three tantalum capacitor types.

Wet tantalum capacitor

A wet tantalum electrolytic capacitor with a non-solid electrolyte, often a liquid, employs tantalum powder immersed in the electrolyte. The dielectric material is typically an oxide layer formed on the surface of the tantalum metal. This oxide, tantalum pentoxide, has a dielectric constant of 26. The tantalum metal serves as the anode, and the cathode is usually made of a conductive material, often manganese dioxide in traditional tantalum capacitors. Another name for a wet tantalum capacitor is liquid tantalum capacitor or non-solid tantalum capacitor.

The formation of the oxide layer in a wet tantalum capacitor is a critical aspect of the construction, as it enables the capacitor to store and release electrical charge effectively. This construction allows for high capacitance and stable performance. The high volumetric efficiency of tantalum capacitors make them suitable for space-constrained applications. Wet tantalum capacitors find use in a wide range of applications including power supply circuits, audio equipment, and communication devices.

Characteristics of a wet tantalum capacitor

- High Capacitance

- High stability

- Operates effectively in a wide temperature range

- Provides reliable performance in harsh environmental conditions

- Capable of extended operational life

Wet tantalum capacitor uses

- Commonly used in military and aerospace applications.

Solid tantalum capacitor

A solid tantalum capacitor features tantalum metal serving as the anode and a solid manganese dioxide layer acting as both the cathode and electrolyte. This design enhances reliability and stability while eliminating the risks associated with liquid electrolytes, such as leakage. These capacitors are compact in size and offer high capacitance and and excellent reliability.

The compact size of solid tantalum capacitors, coupled with their high capacitance, makes them suitable for a wide range of electronic applications. They find extensive use in devices where space efficiency, dependability, and stable performance are crucial, including medical implants, telecommunications equipment, and aerospace electronics. The robust construction of solid tantalum capacitors ensures optimal performance in diverse environmental conditions.

Characteristics of a solid tantalum capacitor

- High reliability construction

- Stability: Provides stable performance in diverse environmental conditions.

- Compact design suitable for miniaturized electronic devices.

- Solid-state design eliminates the risk of electrolyte leakage.

- Durable hence well-suited for applications where durability is crucial.

- Operates effectively across a range of temperatures.

Solid tantalum capacitor uses

- Solid tantalum capacitors find applications in medical implants, telecommunications, and aerospace electronics.

Polymer capacitor

What is a polymer capacitor? This is a type of tantalum capacitor that utilizes a conductive polymer instead of manganese dioxide. This conductive polymer serves as both the cathode electrode and the electrolyte in the polymer tantalum capacitor. Like in traditional tantalum capacitors, tantalum metal serves as the anode.

Polymer tantalum capacitors offer stable capacitance across a broad temperature range and excel in high-frequency applications, making them ideal for demanding electronics such as power supplies, telecommunications equipment, and portable devices. Combining the advantages of solid construction with a conductive polymer electrolyte, these capacitors strike a balance between high capacitance, low equivalent series resistance (ESR), and prolonged operational life, catering to the evolving needs of contemporary electronic designs.

Characteristics of a polymer capacitor

- Lower ESR compared to traditional tantalum capacitors.

- Reduced internal heating, contributing to improved reliability.

- Maintains stable capacitance over a broad temperature range.

- Improved high-frequency performance

- Applications: Well-suited for power supplies, telecommunications equipment, and portable devices.

- Strikes a balance between high capacitance, low ESR, and extended operational life.

- Construction ensures space efficiency

Polymer capacitor uses

- Polymer capacitors are suitable for use in medical implants, telecommunications, and aerospace electronics.

Conclusion

Engineers employ different tantalum capacitor types in circuits for various applications. Tantalum electrolytic capacitors utilize liquid electrolyte, providing high capacitance and stability. In contrast, solid tantalum capacitors rely on a solid manganese dioxide layer for enhanced reliability. Polymer tantalum capacitors combine the benefits of solid construction with a conductive polymer electrolyte, offering a balance of performance and space efficiency. As electronics continue to evolve, tantalum capacitors will continue to be indispensable components in a wide variety of applications.

Good read!

Pingback: Types of Capacitors and Their Applications: An Introductory Guide -

Pingback: Polarized vs Non-Polarized Capacitor: Differences and Uses -