Volumetric Efficiency of a Capacitor

The volumetric efficiency of a capacitor is vital for its performance in circuits. This parameter is crucial in the design of portable systems or densely populated circuit boards, where achieving high capacitance in compact dimensions is essential. In this article, we explore what volumetric efficiency means for capacitors, factors influencing it, and its significance in electronic design.

What is volumetric efficiency?

The volumetric efficiency of a capacitor refers to its ability to provide a high capacitance value within a given volume. It quantifies how effectively a capacitor can store electrical charge relative to its size. In other words, it quantifies the amount of capacitance achievable per unit volume.

A capacitor that exhibits high volumetric efficiency can store more charge, making it ideal for applications with limited space or where compact components are necessary. Generally, manufacturers express the volumetric efficiency in terms of a CV value, where C denotes capacitance and V denotes voltage.

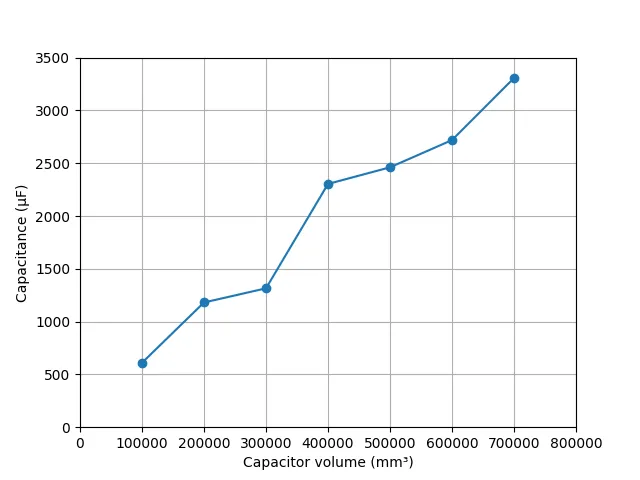

The units of volumetric efficiency are typically expressed as capacitance multiplied by voltage per unit volume. Generally, common units include microfarad volts per cubic centimeter (µFV/cm³) or picofarad volts per cubic millimeter (pFV/mm³). Figure 1 shows a plot of capacitance against volume for an aluminum electrolytic capacitor.

Factors that determine the volumetric efficiency of a capacitor

The main factors that influence the volumetric efficiency include:

- Dielectric material: Dielectric materials with high permittivity (dielectric constant) typically have the highest volumetric efficiency. Some examples include ceramic materials like barium titanate, lead zirconate titanate, and certain types of polymers.

- Dielectric thickness: Thinner dielectric layers allow for more efficient use of space within the capacitor. This leads to higher volumetric efficiency.

- Electrode material: The conductivity of electrode materials influences how efficiently charge can be stored and retrieved within the capacitor.

- Capacitor construction: The physical design and layout of the capacitor, including the arrangement of layers and the spacing between electrodes, can impact its volumetric efficiency.

- Manufacturing process: The precision and quality of the manufacturing process can affect the uniformity and reliability of the capacitor, ultimately influencing its volumetric efficiency.

Implications on circuit design

The volumetric efficiency of capacitors has significant implications for circuit design. High volumetric efficiency capacitors allow for the storage of more charge in smaller physical spaces, enabling the design of more compact and lightweight electronic devices. This is particularly important in portable systems where size and weight constraints are critical.

Additionally, high volumetric efficiency capacitors help optimize the use of available space in densely populated circuit boards. They also facilitate the design of more complex circuits. Overall, considering volumetric efficiency in circuit design ensures efficient use of space and enhances the performance of electronic systems.

Volumetric efficiency of common capacitors

Common capacitor types vary in their volumetric efficiency, with some exhibiting higher efficiency than others.

- Ceramic capacitors exhibit relatively high volumetric efficiency, providing a good balance of capacitance and size.

- Film capacitors also offer decent volumetric efficiency, but they tend to be larger than ceramics for similar capacitance values.

- Mica capacitors offer excellent volumetric efficiency, providing high capacitance in a small package. However, they are less popular due to their higher cost.

- Aluminum electrolytic capacitors have lower volumetric efficiency compared to ceramics and films but can still offer decent capacitance in a relatively compact size.

- Tantalum capacitors, renowned for their exceptional volumetric efficiency, offer high capacitance in a small form factor.