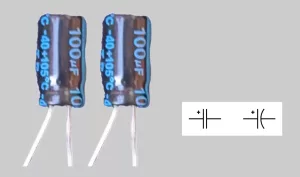

Various aluminum electrolytic capacitor types are used in today’s electronic circuits. But what is an aluminum electrolytic capacitor? Basically, an aluminum electrolytic capacitor is a type of electrolytic capacitor that uses aluminum as one of its electrodes. These capacitors are widely used in electronic circuits for their impressive ability to store and release electrical energy. A typical aluminum electrolytic capacitor consists of two aluminum foils separated by a thin layer of aluminum oxide, which acts as the dielectric.

Aluminum electrolytic capacitors find applications in various electronic devices, including power supplies, audio equipment, and electronic filters. These capacitors are polarized and reversing the polarity of a component can damage it. This article explores various aspects of different aluminum electrolytic capacitor types including their classes, characteristics and applications.

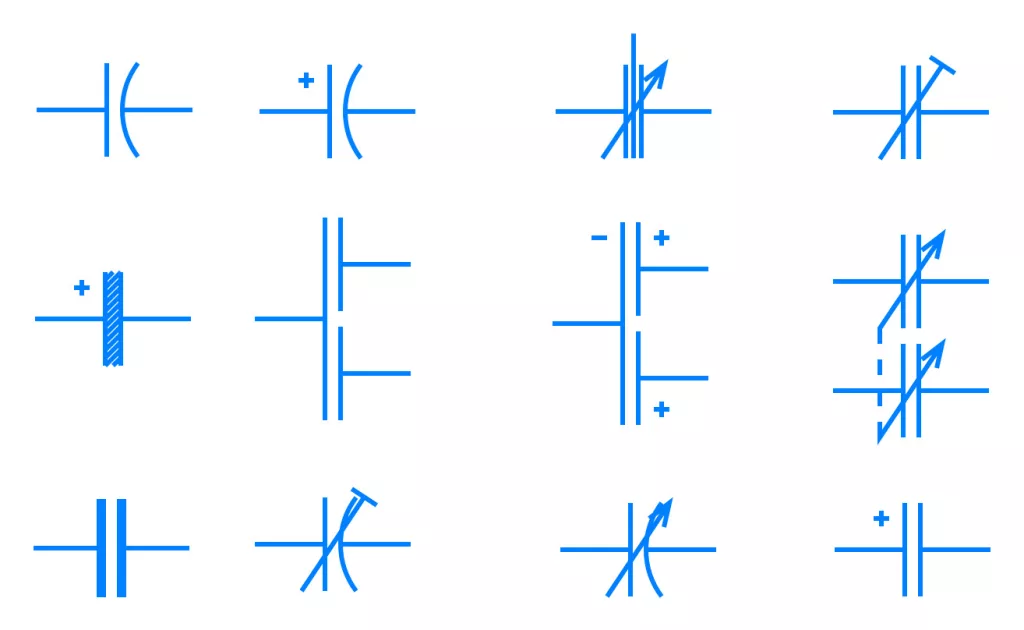

Aluminum electrolytic capacitor symbol

The symbols shown in Figure 1 are used to denote an aluminum electrolytic capacitor. While both symbols are commonly used in the US, there are locations that are known to prefer one.

Aluminum electrolytic capacitor construction

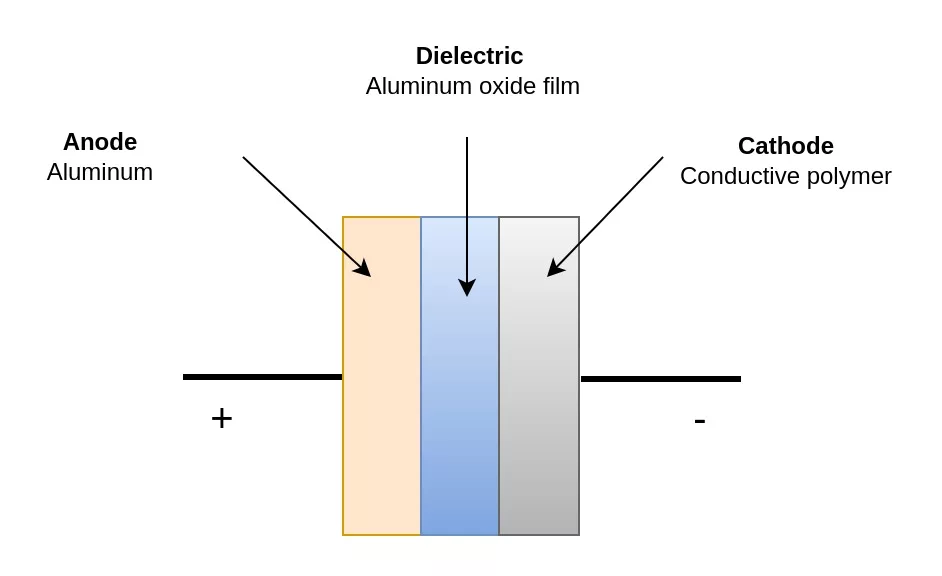

Aluminum electrolytic capacitors are specially engineered to offer efficient energy storage. A typical aluminum electrolytic capacitor consists of two aluminum foils, one acting as the anode and the other as the cathode. The two are separated by a thin dielectric oxide layer formed through an anodization process. The foils are tightly wound together, creating a compact and space-efficient cylindrical structure. This winding is immersed in a conductive electrolyte, typically a liquid or gel, enhancing the capacitor’s capacitance.

To prevent a short circuit in aluminum electrolytic capacitors, a paper separator is often inserted between the aluminum foils. The entire assembly is enclosed in a case, usually made of aluminum or plastic, and sealed to protect the capacitor from external environmental factors. This well-engineered structure allows aluminum electrolytic capacitors to deliver high capacitance values within a relatively small and cost-effective design. Figure 2 shows the structure of a polymer aluminum electrolytic capacitor.

Aluminum electrolytic capacitor types

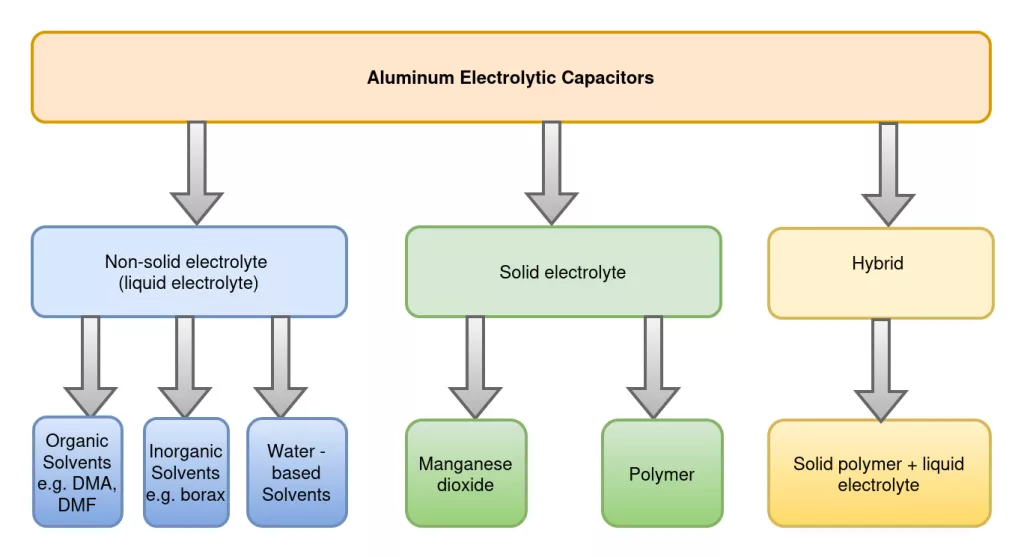

Aluminum electrolytic capacitors can be broadly categorized into three classes: solid electrolyte, non-solid electrolyte and polymer capacitors. Figure 3 shows the electrolytes used in different types of aluminum electrolytic capacitors.

Non-solid aluminum electrolytic capacitor

A non-solid aluminum electrolytic capacitor uses a liquid electrolyte. These capacitors are also commonly referred to as liquid or wet aluminum electrolytic capacitors. Liquid aluminum electrolytic capacitors come in a hermetically sealed can. The airtight enclosure protects the liquid electrolyte from external environment factors. Liquid electrolyte capacitors offer a large capacity and are capable of withstanding high voltages. Additionally, these components are inexpensive and come in a variety of capacitance and voltage values and sizes.

Characteristics of liquid aluminum electrolytic capacitor

- They come in a variety of capacitance values, voltage ratings, and sizes.

- They have a limited service life.

- They are inexpensive.

Applications of liquid aluminum electrolytic capacitors

- Smoothing in power supplies and DC-DC converters

- DC link uses in drives and inverters

Solid aluminum electrolytic capacitors

A solid-electrolyte aluminum electrolytic capacitor uses a solid conductive polymer material as the dielectric. These capacitors are available in both can and resin-molded surface-mounted designs. Since these capacitors utilize solid electrolyte, they do not require hermetic sealing.

Compared to liquid electrolyte capacitor types, solid aluminum electrolytic capacitors offer longer life, improved stability, and lower equivalent series resistance (ESR). Furthermore, they can withstand higher inrush and ripple currents. Solid aluminum electrolytic capacitors find application in a broad range of uses, including coupling, decoupling, smoothing, and filtering. However, it’s worth noting that these capacitors are generally more expensive than their liquid counterparts.

Characteristics of solid aluminum electrolytic capacitors

- Stable electrical characteristics

- Stable thermal characteristics

- High tolerance to inrush currents

- High tolerance to ripple currents

- Lower ESR compared to wet aluminum electrolytic capacitors

Applications of solid aluminum electrolytic capacitors

- Coupling

- Decoupling

- Smoothing

- Filtering

Polymer aluminum electrolytic capacitor

A polymer aluminum electrolytic capacitor utilizes a conductive polymer as the electrolyte. Unlike conventional aluminum electrolytic capacitors, the cathode of a polymer capacitor features a conductive polymer coating. The use of a solid polymer electrolyte offers advantages such as lower ESR, longer operational life, and improved stability.

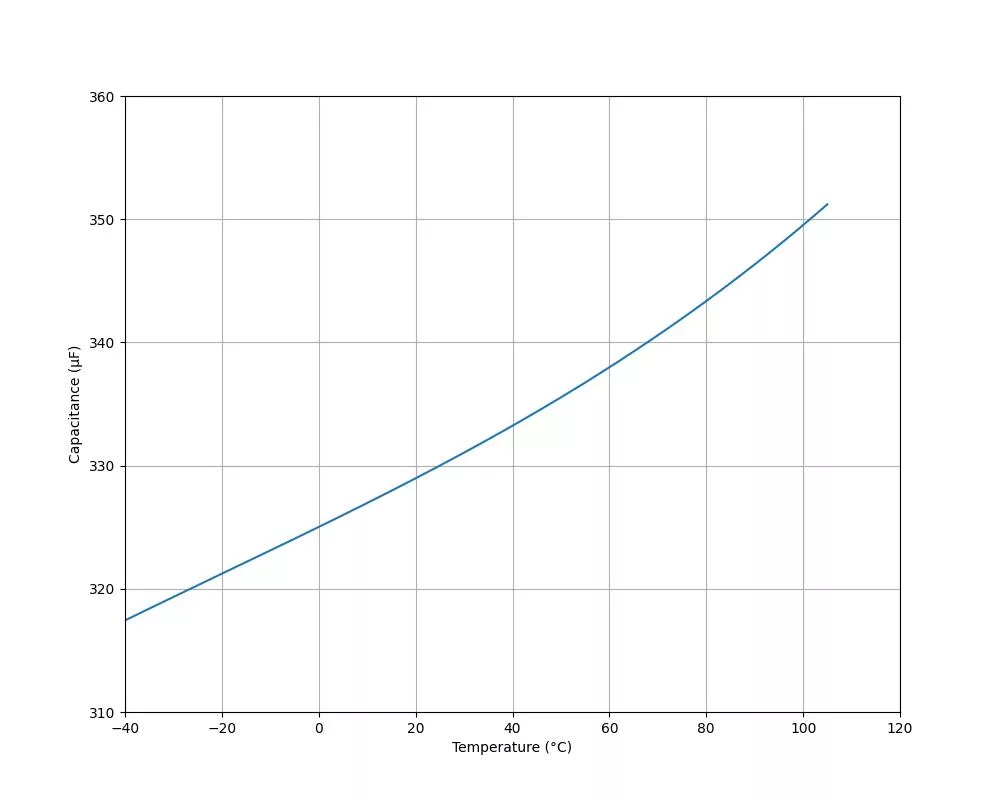

Polymer capacitors are ideal for applications where high capacitance values, compact size, and reliability are essential, such as in power supplies and various consumer electronics. Figure 4 shows the temperature characteristics of a polymer capacitor.

Characteristics of a polymer capacitor

- High leakage current compared to wet and solid aluminum electrolytic capacitors

- High ripple current ratings

- Longer service life than wet aluminum electrolytic capacitors

- Low ESR

- Small case sizes

Applications of a polymer capacitor

- Buffer applications in power supply systems

- Bypassing and decoupling in space-limited applications

- Decoupling

Hybrid polymer aluminum electrolytic capacitor

A hybrid polymer aluminum capacitor utilizes a combination of a liquid electrolyte and a solid polymer electrolyte. This construction combines the benefits of liquid aluminum electrolytic capacitors and polymer capacitors. The liquid electrolyte provides the oxygen required for the self-healing process. These hybrid capacitors offer low ESR values and moderate stability over time and frequency. The characteristics of these components make them suitable for a wide range of applications in industrial equipment.

Characteristics of a hybrid polymer capacitor

- High tolerance to inrush currents

- High ripple current ratings

- Small case sizes

- Low ESR

- High voltage ratings

Conclusion

In conclusion, aluminum electrolytic capacitors are essential components in today’s electronics. They come in types like liquid, solid, polymer, and hybrid capacitors, each offering unique benefits. These capacitors efficiently store energy and power a variety of devices including industry equipment and consumer electronics. As technology progresses, these capacitors continue to evolve, ensuring their continued significance in modern electronics.