Ceramic capacitors are essential components in electronic circuits. What is a ceramic capacitor? A ceramic capacitor is a type of capacitor that utilizes ceramic as the dielectric material. The ceramic dielectric allows for high capacitance values within a compact size, making these capacitors ideal for space-limited applications.

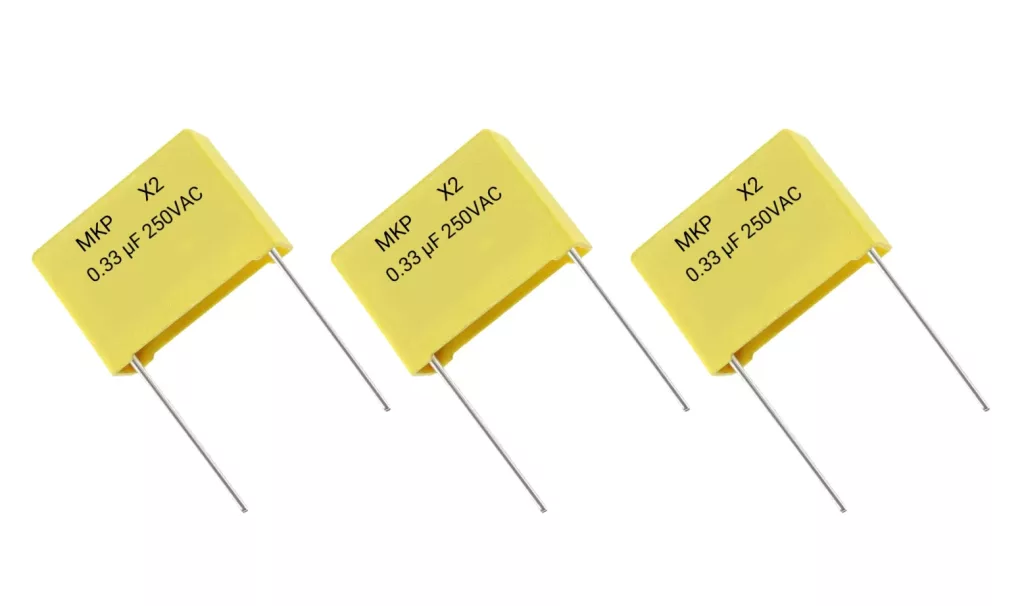

Ceramic capacitors come in various shapes and sizes, providing versatility for a range of applications. They are non-polar components and are used in circuits for a wide range of applications including smoothing, filtering, coupling, and decoupling. In this article, we explore the different ceramic capacitor types and their uses.

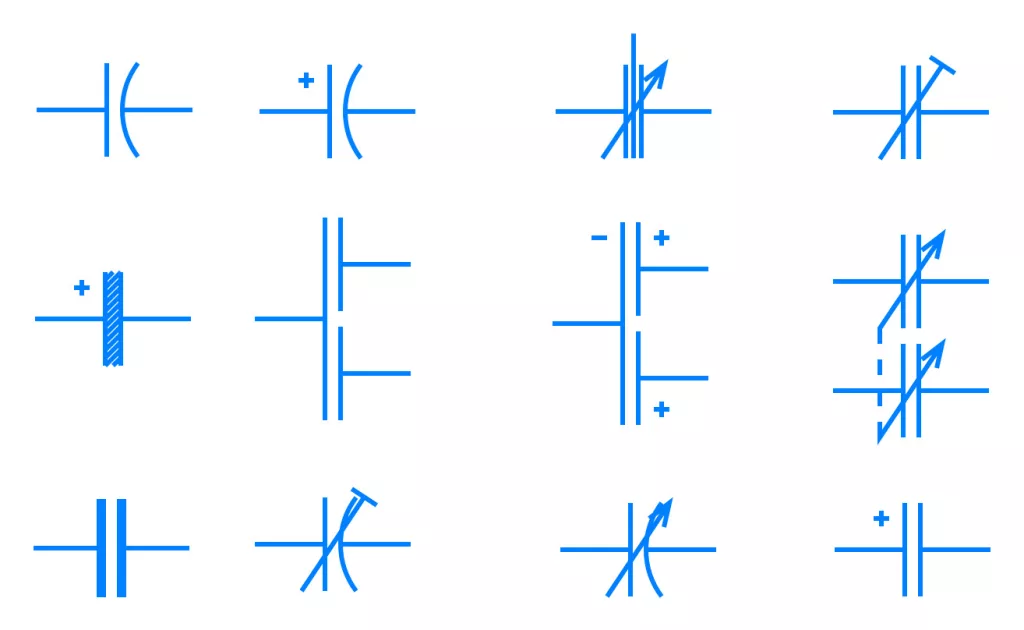

Ceramic capacitor polarity and symbol

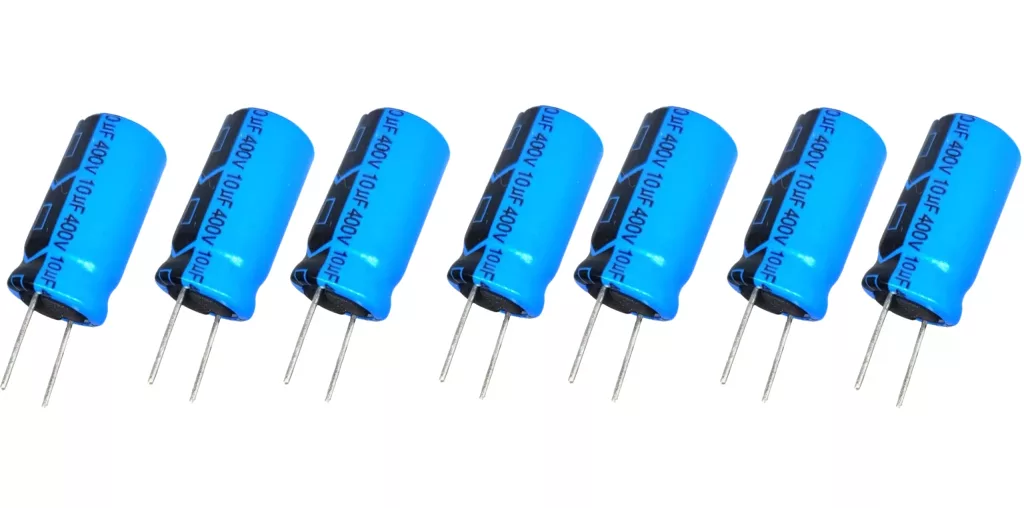

Unlike electrolytic capacitors that are polarized, ceramic capacitors are generally non-polarized. This means that they can be connected in any orientation within a circuit. This lack of polarity simplifies their integration and enhances their ease of use. Like other non-polarized capacitors, a ceramic capacitor uses the symbol shown in Figure 1. Also shown in Figure 1 is an SMD ceramic capacitor.

Ceramic capacitor construction

A ceramic capacitor consists of two plates separated by a ceramic material called a dielectric. The dielectric is essential for their function, as it enables the storage and release of electrical energy. The plates and the dielectric are stacked together and then coated with a protective layer. This straightforward construction allows ceramic capacitors to be compact yet efficient in storing and delivering electrical charges within electronic circuits.

Ceramic capacitors come in two main constructions: single-layer and multilayer ceramic (MLCC) types. The choice between these constructions depends on the specific requirements of the circuit and the desired balance between simplicity and enhanced capacitance.

Single-layer capacitor

In a single-layer design, a single ceramic layer serves as the dielectric between two plates, keeping the construction simple and cost-effective. These capacitors come in different forms including disc ceramic and plate ceramic capacitors. Disc ceramic capacitors have a simple, disc-shaped design. They consist of a ceramic disc with electrodes on either side. These capacitors are commonly used in low-frequency applications and basic electronic circuits.

Multilayer ceramic capacitor (MLCC)

A multilayer ceramic capacitor consists of multiple layers of ceramic material interleaved with metal electrodes. This construction allows MLCCs to achieve high capacitance values within a small footprint. They are widely utilized for decoupling, filtering, and energy storage in electronic circuits. MLCCs offer versatility across various industries due to their stable performance, reliability, and compatibility with surface mount technology (SMT).

Classification of ceramic capacitors dielectrics

There are two standards that classify commonly available dielectric materials: the International Electrotechnical Commission (IEC) and the Electronic Industries Alliance (EIA). The EIA standard employs Roman numerals to number the classes, while, in contrast, the IEC standard uses Arabic numbers.

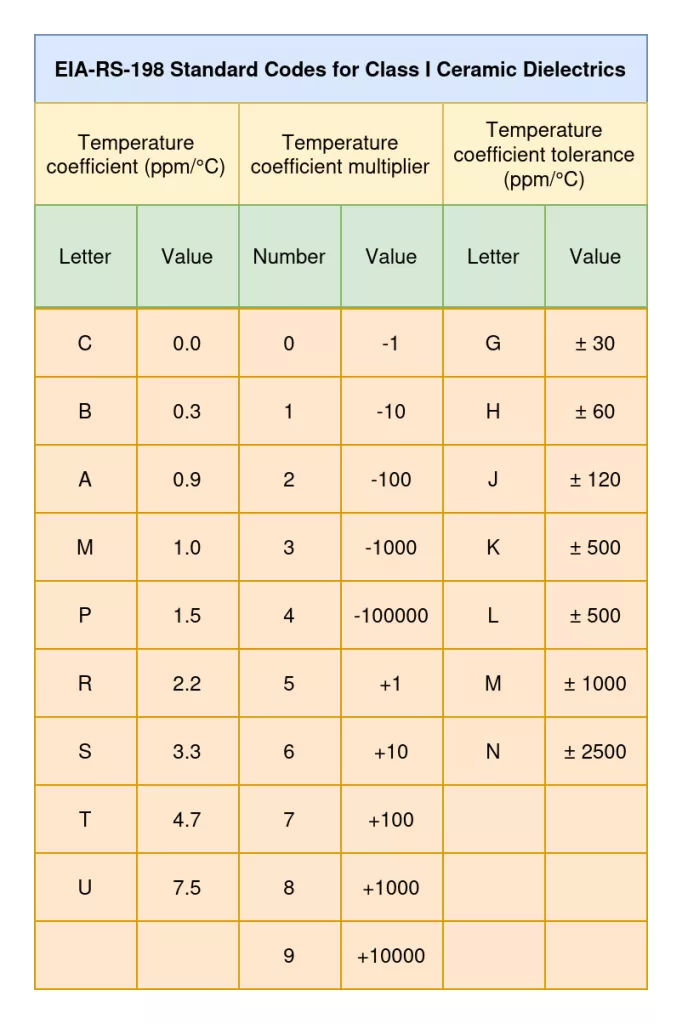

The following section explores each of these classes based on the EIA standard (EIA-RS-198). Table 1 shows the temperature characteristics of Class I dielectrics as defined by the EIA-RS-198 Standard.

Class I ceramic capacitors

Class I capacitors are known for their remarkable stability under different conditions. These capacitors predominantly use calcium zirconate as their dielectric material. This material is characterized by high temperature stability and a lower relative permittivity than Class II dielectric material.

Class I ceramic capacitors are characterized by high stability, low losses, and minimal variation in capacitance over various environmental conditions. The most common example of Class I ceramic capacitors are C0G (NP0) and U2J capacitors. Here are the key characteristics of Class I ceramic capacitors, particularly C0G:

- High temperature stability

- Minimal capacitance variation with changes in temperature, voltage, and frequency.

- Low dielectric absorption

- High Q factor

- C0G capacitors maintain stable performance at high frequencies

- High reliability

- Not susceptible to aging

- Low volumetric efficiency

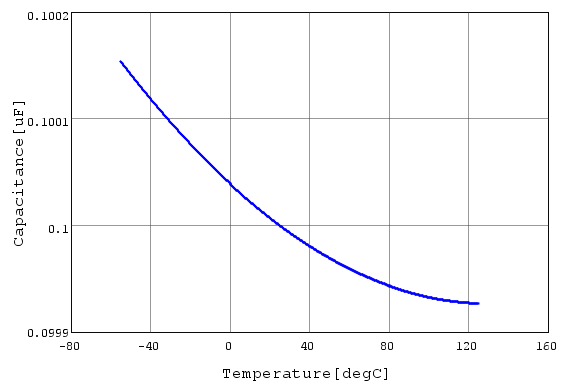

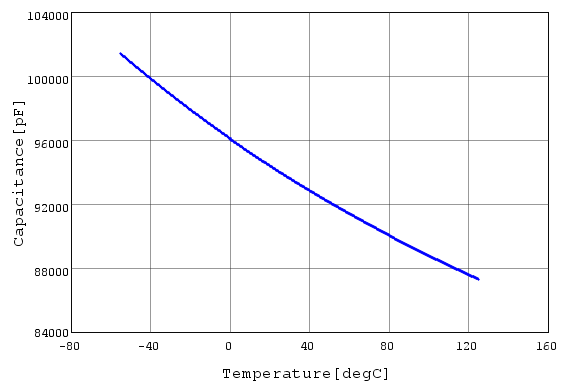

Class I ceramic capacitors are often used in precision applications, such as oscillators, filters, and other circuits where reliable performance is essential. Figure 2 and 3 show the temperature characteristics of general purpose C0G and U2J capacitors, respectively. Other examples in this class of ceramic capacitors include M7G, H2G, L2G, P2H, R2H, S2H, T2H, Q3K and P3K.

Class II ceramic capacitors

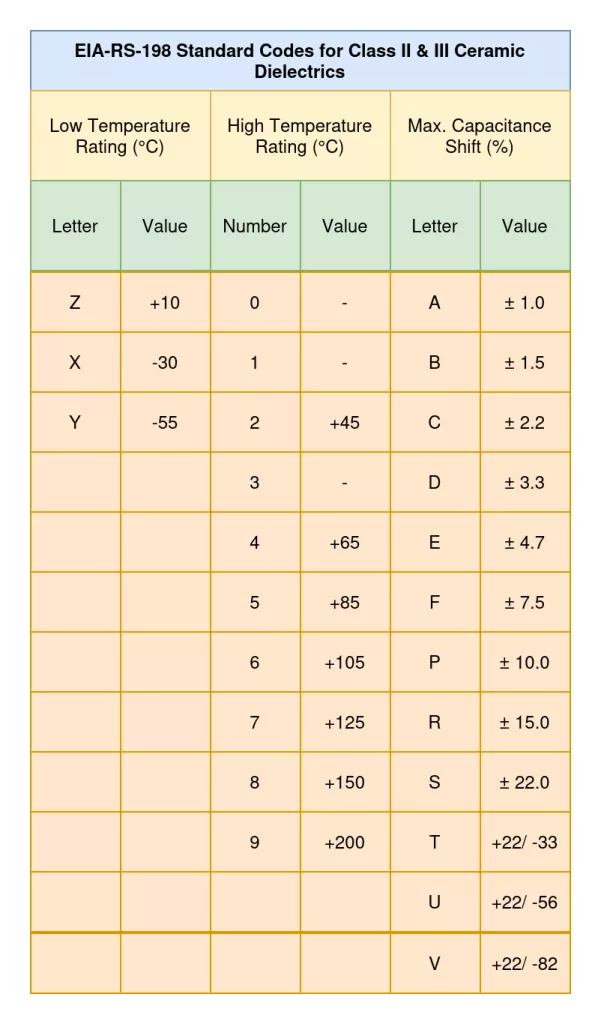

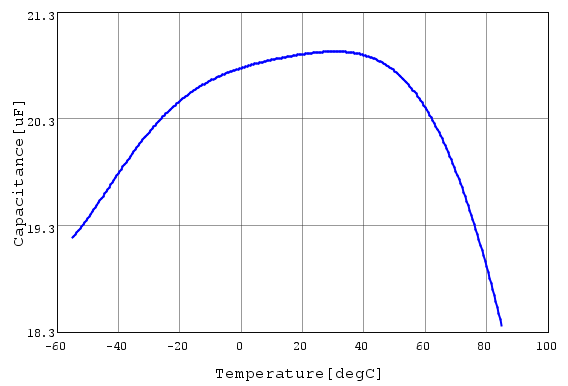

Class II ceramic capacitors primarily utilize barium titanate as the dielectric material. This dielectric exhibits a high dielectric constant yielding high capacitance values. On the flip side, this material is not stable over temperature. Table 2 shows the temperature characteristics of Class II and III ceramic dielectrics as defined by the EIA-RS-198 Standard. Figure 4 shows the temperature characteristics of a general purpose X5R capacitor.

Class II ceramic capacitors are characterized by higher capacitance values compared to Class I capacitors. However, unlike Class I counterparts, these capacitors may exhibit larger variations in capacitance with changes in temperature, voltage, and frequency. The most common examples of Class II ceramic capacitors include X7R and X5R. Here are some general characteristics of Class II ceramic capacitors:

- Higher capacitance.

- Moderate temperature stability.

- Moderate dielectric absorption:

- Capacitance may vary with changes in applied voltage.

- Wider range of applications

- Susceptible to aging

- Moderate volumetric efficiency

Class II capacitors find uses in a broad range of applications where the higher capacitance values offset the trade-offs in temperature stability and other characteristics.

Class III ceramic capacitors

Class III ceramic capacitors, like Z5U and Y5V, have very high capacitance but are not stable with temperature changes. Z5U capacitors, for instance, can vary a lot (up to -56%) between 10°C and 85°C. Even though they are made with the same material as Class II capacitors, the difference comes from how manufacturers use additives to improve stability. Moreover, Class II and III ceramic capacitors are ferroelectric and thus susceptible to aging effects. The key characteristics of Class III capacitors include:

- High volumetric efficiency

- Poor stability

- Susceptible to aging

Class III ceramic capacitors are commonly used in bypass applications and other general-purpose uses where stability, insulation resistance, and dielectric losses are not critical.

Applications of different ceramic capacitor types

The versatility of ceramic capacitors, along with their compact size and cost-effectiveness, makes them essential components in a wide range of electronic devices and systems. These components are commonly used in the following applications:

- Decoupling and bypassing: ceramic capacitors help stabilize voltage levels in electronic circuits, preventing noise and fluctuations. They are often used in parallel with power supply lines to decouple and bypass high-frequency signals.

- Filtering: ceramic capacitors are employed in filters to remove unwanted signals or noise from the electronic circuit. They play a crucial role in smoothing the output voltage in power supply circuits.

- Timing and oscillation: in timing circuits and oscillators, ceramic capacitors are used to determine the frequency of oscillation. They are integral components in producing accurate and stable clock signals.

- Coupling and DC blocking: Ceramic capacitors allow AC signals to pass while blocking DC components. This is useful in coupling and blocking unwanted DC offsets in amplifiers and other circuits.

- Tuning: ceramic capacitors are used for tuning radio frequency (RF) circuits and adjusting the resonance frequency of antennas.

- Signal coupling and decoupling: They facilitate the transfer of AC signals between different stages of an electronic circuit while blocking any DC components.

- Energy storage: In certain applications, ceramic capacitors are used for energy storage in backup circuits or for providing short bursts of energy.

- Temperature compensation: certain types of ceramic capacitors, such as C0G, are used for their stability over temperature variations and find applications in precision circuits where temperature changes could affect performance.

Conclusion

In summary, ceramic capacitors are widely used in today’s electronic circuits. According to the EIA, these capacitors fall into three classes: Class I, Class II, and Class III. Class I is super stable and great for precise circuits. Using using barium titanate, a Class II capacitor provides high capacitance but is a bit sensitive to temperature. Class III ceramic capacitors, like Z5U, offer high capacitance but struggle with temperature stability. The diversity in the characteristics of these capacitors makes them a suitable choice for a variety of applications, establishing them as the most used capacitors in today’s circuits.

Pingback: Polarized vs Non-Polarized Capacitor: Differences and Uses -