Film capacitors are named for their dielectric material and come in two main types: film and foil and metallized foil. Film and foil capacitors are known for their larger and more rugged construction. On the other hand, metallized film capacitors feature a metallized layer and are smaller and pricier.

Film capacitors cover a range from around .0005uF to over 30 uF and support a wide range of operating voltages, typically from 10VDC to above 2000 VDC. Generally, these capacitors exhibit good temperature stability, low dielectric absorption, and a reliable AC response. Although metallized film capacitors are smaller and pricier, the two constructions deliver comparable performance. Both types play a significant role in electronic circuits, offering engineers versatile options and reliable performance. This article explores the various types of film capacitors that are commonly used in today’s electronic circuits.

Types of film capacitors

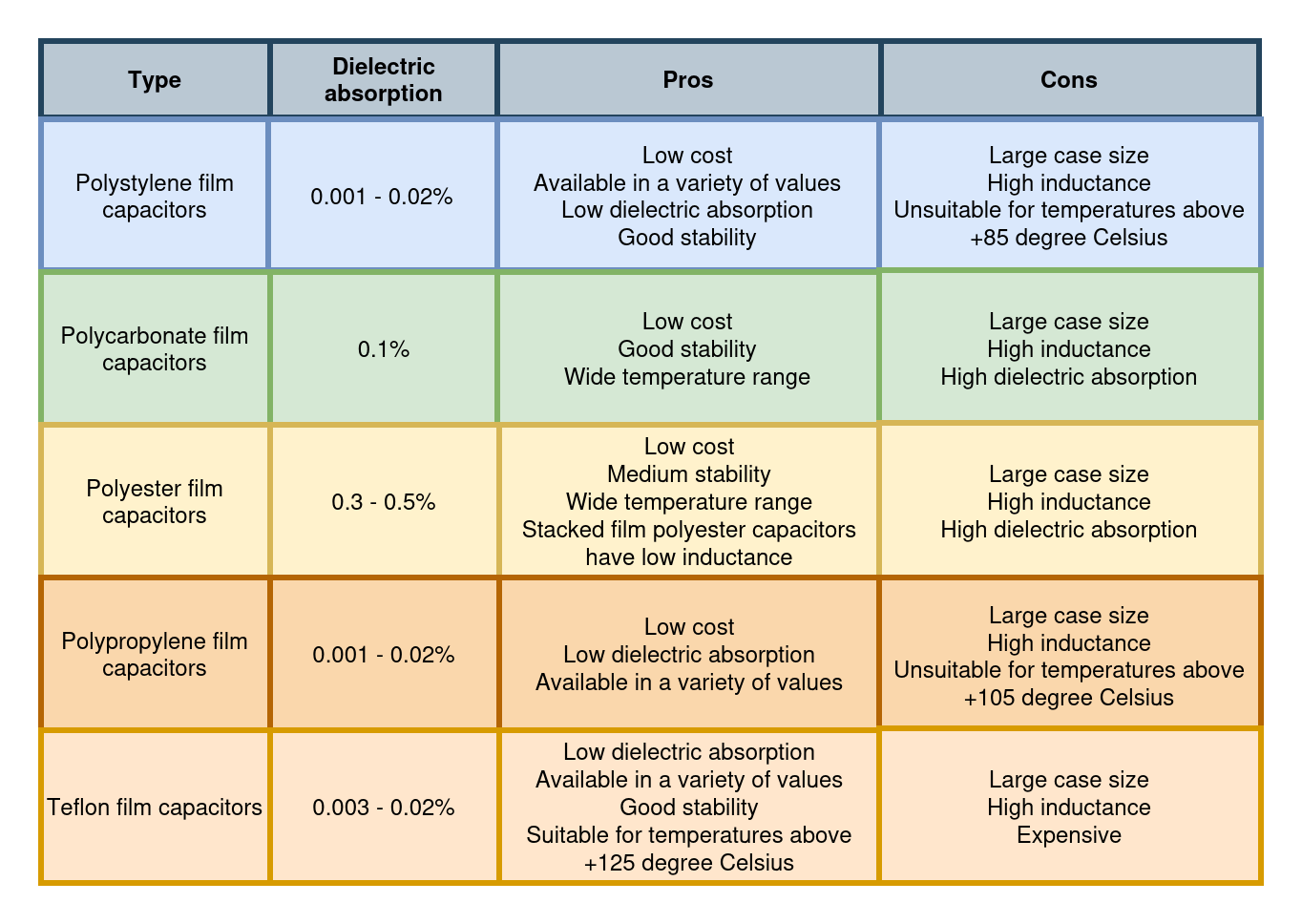

Film capacitors are one of the most common types of capacitors used in electronics systems today. The most widely used types of film capacitors include polyester, polycarbonate, polystyrene, polypropylene, polysulfone, and Teflon capacitors. A comparison chart of various film capacitors is shown in Table 1.

Table 1: A comparison chart showing dielectric absorption values, pros, and cons of various types of film capacitors.

Polyester capacitors

Polyester film capacitors, also known as Mylar capacitors, are a popular choice, featuring polyester as their dielectric material. Available in both film and foil as well as metallized varieties, they offer an economical solution with voltage capacities ranging from 50VDC to 1000VDC. One of their main drawbacks is that they exhibit a high dielectric absorption, typically 0.2 to 0.5%. This characteristic limits their suitability for applications such as critical timing applications.

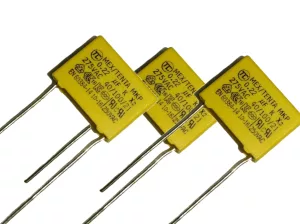

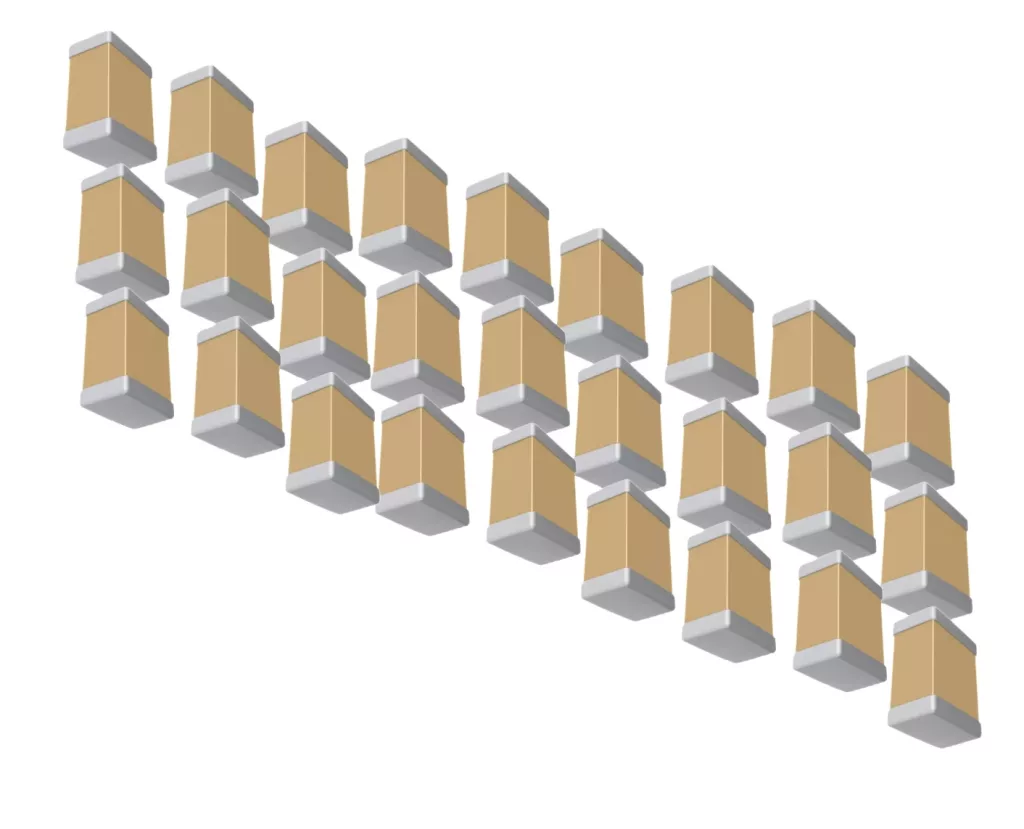

Polyester film capacitors showcase a unique non-linear temperature coefficient, where capacitance increases at higher temperatures and decreases at lower temperatures. Within the temperature range of 25 to 85 degrees Celsius, a rising temperature coefficient is observed. Mylar capacitors are commonly used in a broad range of applications including audio coupling, semi-critical timing circuits, and tone controls. Figure 2 shows 0.1 µF polyester film capacitors.

Figure 2: 0.1 µF polyester film capacitors

Polycarbonate capacitors

Polycarbonate film capacitors are a reliable alternative to polystyrene, excelling in critical coupling and timing applications. They exhibit linearity within a limited temperature range of 25 to 85 degrees Celsius and their temperature stability is lower compared to polystyrene film capacitors. An advantage of polycarbonate capacitors is their resilience to higher temperatures, reaching a maximum of 125 degrees Celsius. This durability allows them to be constructed in metallized film form. Furthermore, these capacitors have a dielectric absorption of approximately 0.08% and cover voltage ranges extending to several thousand volts. Despite a moderate level of moisture sensitivity, the overall characteristics of polycarbonate capacitors make them suitable for various electronic applications.

Polypropylene capacitors

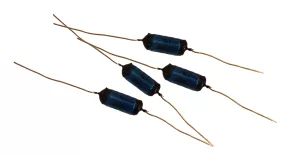

Polypropylene film capacitors boast a negative temperature coefficient of -150 ppm. They offer a low dielectric absorption of .02% and can handle temperatures up to a maximum of 105 degrees Celsius. If their negative temperature coefficient is not an issue, they make a good replacement for polystyrene. Compared to polyester film capacitors, polypropylene film capacitors are a bit larger but offer better electrical characteristics. Figure 3 shows metallized film polypropylene film capacitors.

Figure 3: 0.22 µF metallized polypropylene film capacitors

Polystyrene capacitors

Polystyrene film capacitors stand out as the best in the capacitor world, boasting impressive electrical traits. These capacitors have low temperature coefficients, typically below 120 ppm, with special components featuring super low temperature coefficients, typically ranging from 30-40 ppm. This characteristic ensures linearity across the temperature spectrum found in most electronic devices.

Polystyrene film capacitors also have the lowest dielectric absorption among all capacitor types at 0.02%, making them the go-to components for critical timing circuits and applications. On the flip side, polystyrene capacitors are unsuitable for temperatures exceeding 85 degrees Celsius and are not available in metallized versions. Furthermore, these capacitors are delicate and require careful soldering, making them less suited for automated production setups. Figure 4 shows polystyrene film capacitors.

Teflon capacitors

Teflon film capacitors match polystyrene’s performance and excel at high temperatures. These capacitors are moisture-resistant with a low dielectric absorption of around 0.02%. Teflon film capacitors have higher price limits and are mostly used in mission-critical applications such as aerospace. Furthermore, they are not available in metallized film constructions.

Polysulfone capacitors

Polysulfone film capacitors match polycarbonate specs but are capable of handling temperatures of up to 150 degrees Celsius. These capacitors show good linearity from 25 degrees Celsius upwards, with a slight dip at lower temperatures. While a bit moisture-sensitive, they maintain a dielectric absorption around 0.08%. Polysulfone film capacitors are perfect for scenarios needing robust high-temperature performance and are rarely used in general purpose applications.

Conclusion

In conclusion, film capacitors offer engineers and circuit designers versatile options and reliable performance in electronic circuits. From the robust construction of film and foil to the compact yet efficient design of metallized film, engineers and circuit designers can leverage a spectrum of options. The diverse range of capacitance values, wide voltage support, and excellent temperature stability underline their versatility. Film capacitors remain indispensable for various applications in today’s electronic circuits.

Pingback: Polarized vs Non-Polarized Capacitor: Differences and Uses -