The insulation resistance (IR) of a capacitor influences its reliability and effectiveness in a circuit. Understanding the insulation resistance of a capacitor is important because the characteristic influences the storage and release of electrical energy within a component. This article explores the intricacies of insulation resistance, providing valuable insights and considerations for selecting capacitors for your application.

What is the insulation resistance of a capacitor?

The insulation resistance of a capacitor refers to its ability to resist the flow of electrical current through its dielectric material. It is also commonly referred to as equivalent parallel resistance (EPR) or simply shunt or parallel resistance.

The insulation resistance of a capacitor is typically inversely proportional to its capacitance. It is expressed in units of resistance [MΩ] or as the CR product [MΩ·µF].

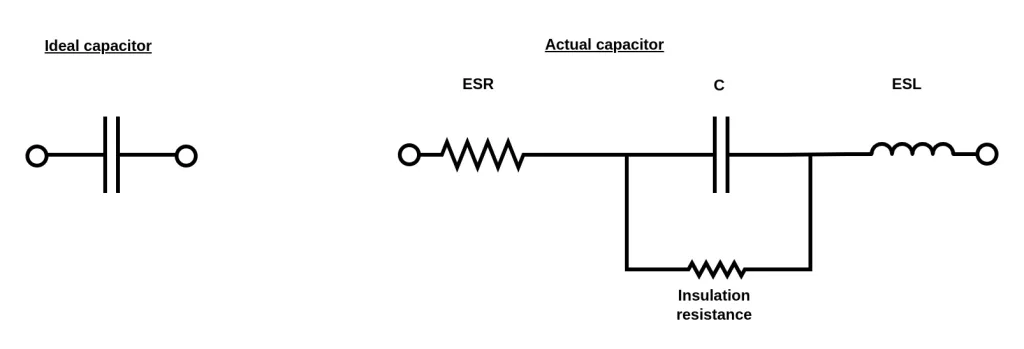

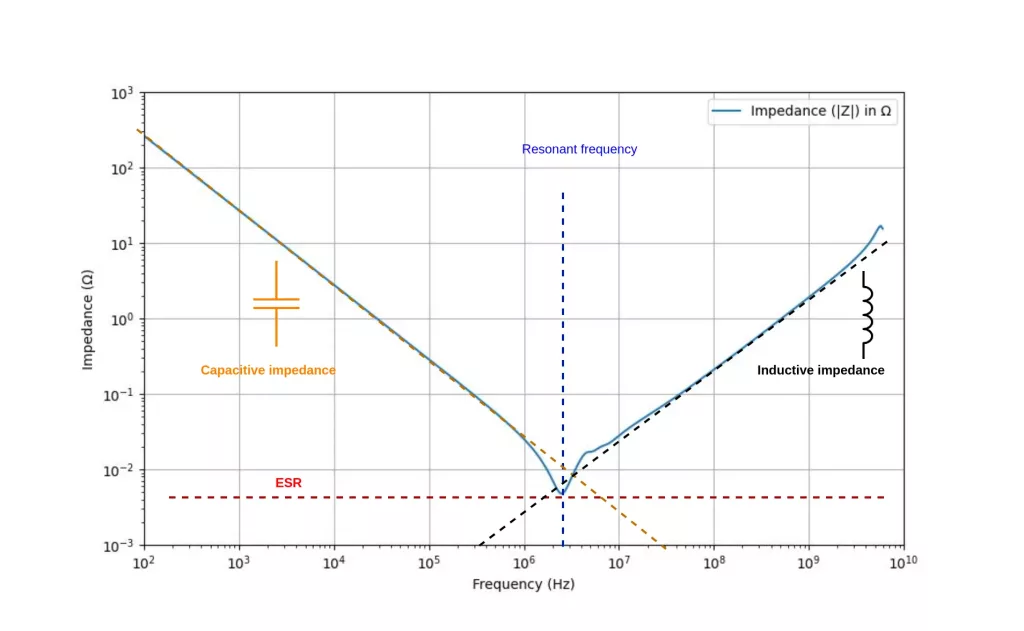

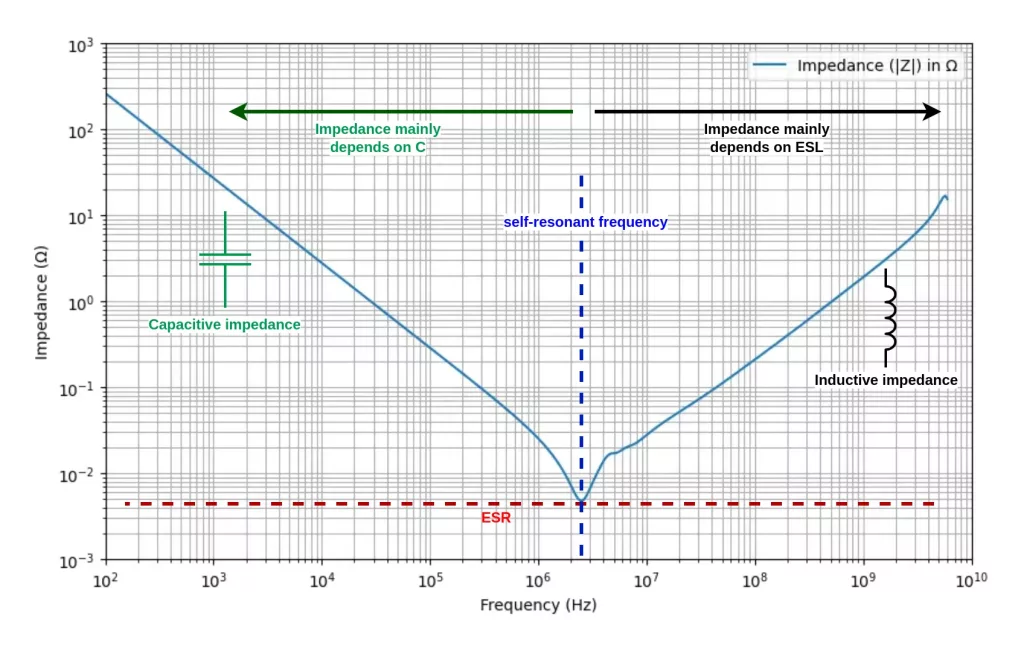

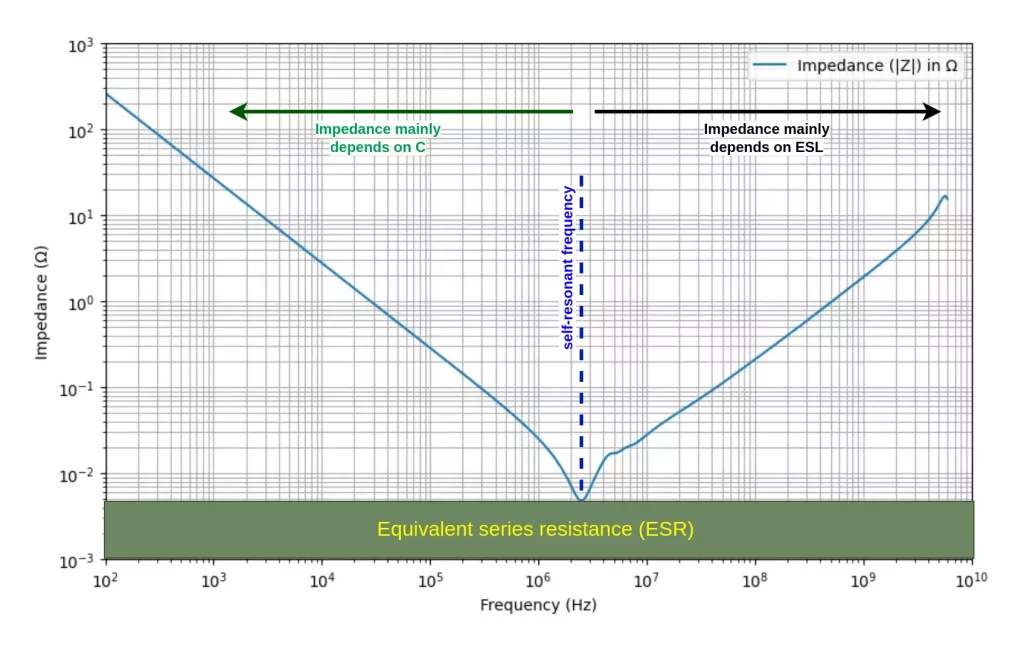

Figure 1 shows a simplified equivalent circuit of an ideal capacitor and an actual capacitor. The additional elements in the circuit of an actual component include insulation resistance, equivalent series resistance (ESR) and equivalent series inductance (ESL).

Factors that determine the insulation resistance

The quality and characteristics of the dielectric material used in a capacitor determines its insulation resistance characteristics. Let us first consider an ideal capacitor. Since an ideal capacitor has an insulator with a perfect atomic lattice structure, there is no movement of free electrons. An ideal capacitor therefore possesses infinite resistivity.

Unlike ideal capacitors, real-world capacitors use imperfect dielectric materials. These insulators feature impurities and defects in the atomic lattice structure. These imperfections introduce charge carriers, leading to some degree of leakage current when an electric field is applied.

The thickness, composition, and overall condition of the dielectric play a significant role in influencing the insulation resistance. A higher-quality dielectric tends to provide better insulation and, consequently, higher resistance. Additionally, differences in resistivity at the surface of a dielectric material influence the insulation resistance of a capacitor.

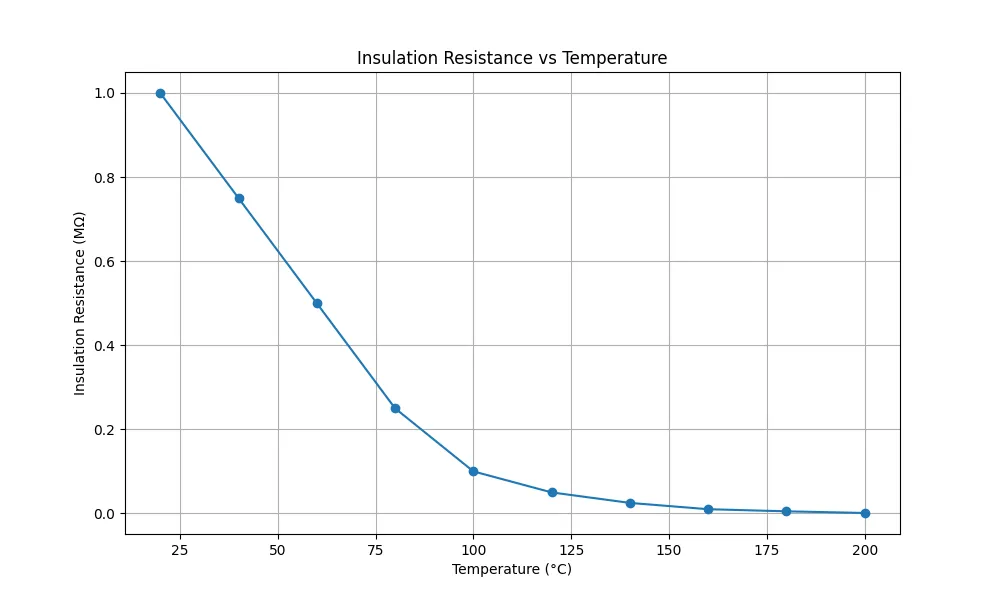

For chip capacitors, factors such as the dielectric formulation, processing methods, and the temperature at the time of measurement influence the insulation resistance.Generally, resistivity tends to decrease with higher temperatures (see Figure 3).

How to measure the insulation resistance of a capacitor

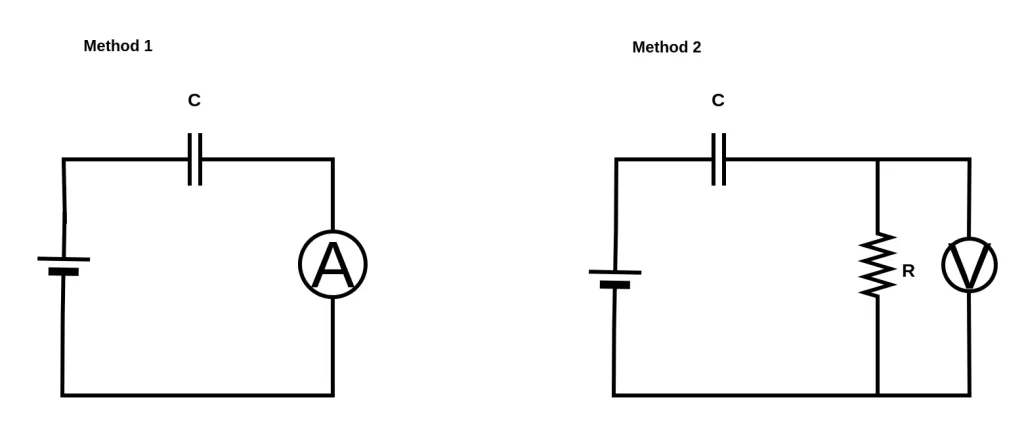

Measuring the insulation resistance of a capacitor involves assessing the dielectric material’s resistance to leakage current. This resistance is intrinsic to the dielectric material itself. To measure IR, the leakage current is determined, and by knowing both the leakage current and applied voltage, the insulation resistance can be calculated using Ohm’s law. Two following methods are commonly used to measure the leakage current:

Method 1

The first method employs an ammeter connected in series with the capacitor and voltage source (see Figure 2a). This method is suitable for capacitors with less than 1uF because the leakage currents are low. High leakage currents can introduce noise and instability, compromising measurement accuracy.

Method 2

The set up for measuring the insulation resistance of a capacitor using this method is as illustrated in Figure 2b. A voltmeter is connected in parallel with a resistor and the two are then connected in series with the capacitor and voltage source. This approach is more effective for accurate measurements, particularly in the presence of higher leakage currents. In addition, this method is suitable for measuring the insulation resistance of capacitors with large capacitance values.

Insulation resistance of common capacitor types

The insulation resistance of a capacitor varies across types due to differences in their dielectric materials. For instance, ceramic capacitors generally exhibit lower insulation resistance while film capacitors boast higher levels. Mica capacitors, on the other hand, feature exceptionally high insulation resistance. This diversity reflects the impact of the dielectric choice on the overall performance of capacitors.

- Ceramic capacitors typically exhibit lower insulation resistance compared to other capacitor types. This characteristic may impact their performance in certain applications where higher insulation resistance is a critical requirement. Figure 3 shows how the insulation resistance of a ceramic capacitor decreases with frequency.

- Aluminum electrolytic capacitors generally possess moderate insulation resistance. While not as high as some film capacitors, their insulation resistance is sufficient for many applications.

- Tantalum capacitors typically exhibit moderate to high insulation resistance. This, coupled with their compact size and stable performance, makes them suitable for applications where reliable insulation is essential.

- Film capacitors, utilizing dielectric materials such as PET (polyethylene terephthalate), PP (polypropylene), PEN (polyethylene naphthalate), PET (polyethylene terephthalate), and PPS (polyphenylene sulfide), offer notably high insulation resistance. This makes them well-suited for applications where robust insulation performance is a crucial consideration in electronic circuits.

- Mica capacitors offer exceptionally high insulation resistance. This characteristic makes them well-suited for applications that demand reliable and durable insulation.

Applications requiring high insulation resistance capacitors

The insulation resistance of a capacitor is one of the factors that determine the reliability and performance of a component. Low insulation resistance can lead to leakage currents and potential electrical failures, compromising the functionality of the circuit. Conversely, high insulation resistance ensures reliable isolation, minimizing the risk of current leakage and enhancing the overall stability of electronic systems. Some of the applications that demand high insulation resistance include:

- Medical electronics: High insulation resistance is vital to guarantee the safety and reliability of sensitive medical devices. It helps to prevent electrical interference and maintain precision in equipment crucial for patient care.

- Aerospace and aviation: Electronic systems on aircraft and spacecraft require high insulation resistance to withstand harsh environmental conditions. This ensures the prevention of electrical failures in avionics and navigation systems, crucial for the safety of air and space travel.

- Power distribution systems: High insulation resistance enhances the efficiency and safety of power grids. By minimizing current leakage, it prevents short circuits and ensures the reliable transmission of energy across the network.

- Telecommunications: In the field of telecommunications, maintaining high insulation resistance is essential for signal integrity. This is crucial in preventing cross-talk and ensuring the stability of data transmission within telecommunication infrastructure.

- Automotive electronics: High insulation resistance is imperative in automotive applications to prevent electrical failures in vehicle control systems. This enhances the overall reliability of electronic components, contributing to the safety and performance of automobiles.

Pingback: ESR of a capacitor and its effects on impedance -